13CrMo4-5 ND Alloy Karfe Bututu maras kyau

Gabatarwar samfur

Kayan aikin injiniya na bututun tukunyar jirgi shine mahimman bayanai don tabbatar da aikin sabis na ƙarshe (kayan aikin injiniya) na ƙarfe, wanda ya dogara da tsarin sinadarai da tsarin kula da zafi na ƙarfe.A cikin ma'auni na bututun ƙarfe, bisa ga buƙatun amfani daban-daban, aikin ƙwanƙwasa (ƙarfin ƙarfi, ƙarfin samar da ƙarfi ko ma'aunin yawan amfanin ƙasa, elongation), kazalika da ma'aunin ƙarfi da taurin ƙarfi, da babban aiki da ƙarancin zafin jiki da masu amfani ke buƙata.

A cikin tsarin samar da bututun ƙarfe maras nauyi don tukunyar jirgi, magani mai zafi shine babban tsari.Maganin zafi yana da tasiri mai mahimmanci a kan ingancin ciki da kuma yanayin yanayin bututun ƙarfe mara nauyi, wanda ke da mahimmanci musamman don samar da bututun ƙarfe mara nauyi.

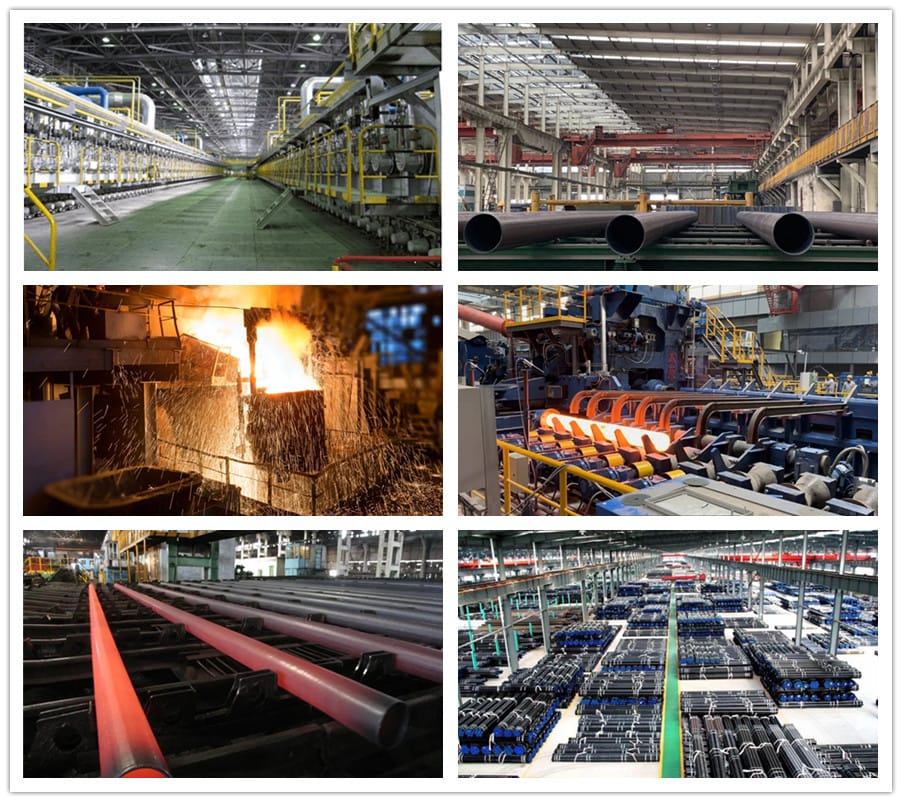

Our kamfanin rungumi dabi'ar ba hadawan abu da iskar shaka zafi magani, da samar da karfe bututu tare da barga metallographic kungiyar da kyau na ciki da kuma waje ingancin surface, ta yin amfani da eddy halin yanzu da ultrasonic atomatik flaw ganewa, karfe bututu daya bayan daya ga eddy halin yanzu aibi ganewa da ultrasonic flaw ganewa.Tare da ma'aunin kauri na ultrasonic da ayyukan gano lahani na oblique, yana iya gano lahani mai laushi a cikin bututun ƙarfe yadda ya kamata.

Hanyar duba ingancin bututun ƙarfe mara nauyi

1. Binciken abubuwan da ke tattare da sinadarai: hanyar bincike na sinadarai, nazarin kayan aiki (kayan infrared CS, sikirin karatun kai tsaye, zcP, da dai sauransu).

2. Surface ingancin dubawa na karfe bututu: 100%

① Duban gani na Manual: yanayin haske, ma'auni, ƙwarewa, ganewa, jujjuya bututun ƙarfe.

② Binciken NDT:

A. Binciken Ultrasonic UT:

B. ET: (Induction na lantarki)

C. MT da gano zubewa:

Gano aibi na Magnetic, wanda ya dace da gano saman da lahani na kusa da kayan ferromagnetic.

D. Gano aibi na Electromagnetic ultrasonic:

Babu matsakaicin haɗin kai da ake buƙata, wanda za'a iya amfani da shi zuwa babban zafin jiki da saurin gudu, m da busassun bututun bututun ƙarfe na gano lahani.

E. gwajin shigar ruwa:

Fluorescence, canza launi, da gano lahani na bututun ƙarfe.

3. Binciken aikin jiki da sinadarai na bututun karfe;

4. Tsari aikin dubawa na karfe bututu;

Cikakken Bayani

| Matsayin Karfe: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10,SA192 ST35.8,ST45.8,STB340,STBA 12-2,API5L,5CT,ND-karfe bututu |

| Daidaito: | ASME/ASTM SA/A53/513/106/209/210/213/335/178/179/519 ASME/ASTM SA/A213,A312,A269,A778,A789, DIN 17456, DIN17457, DIN 17459, DIN17175, EN10216, BS3605, BS3059 |

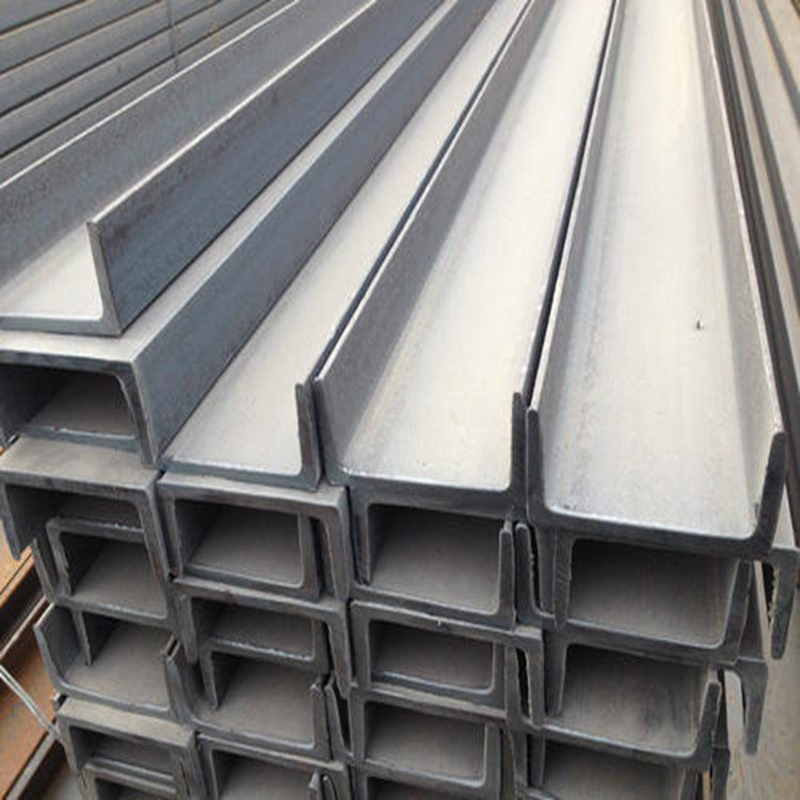

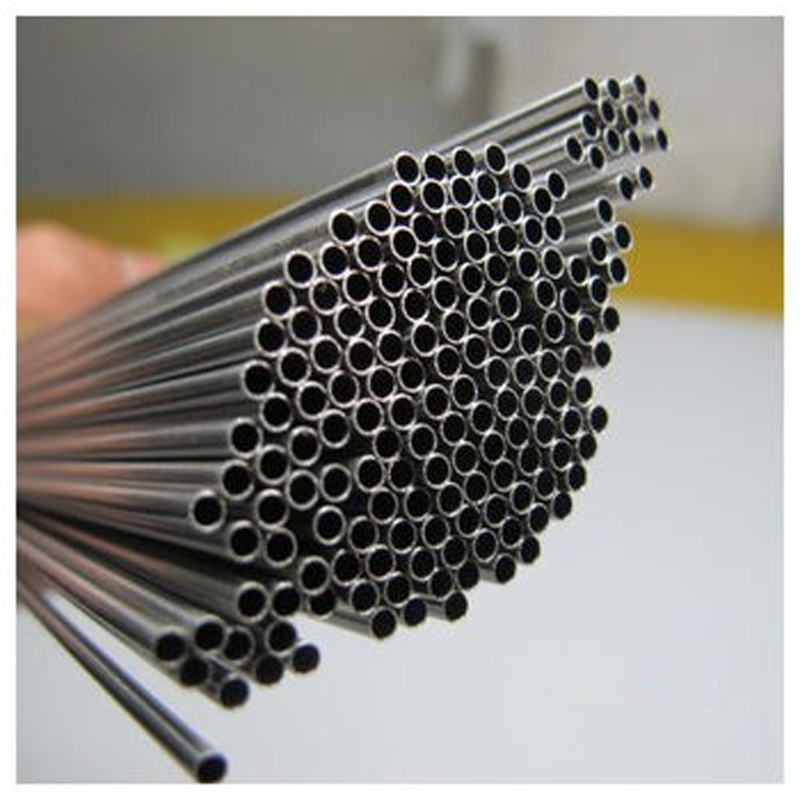

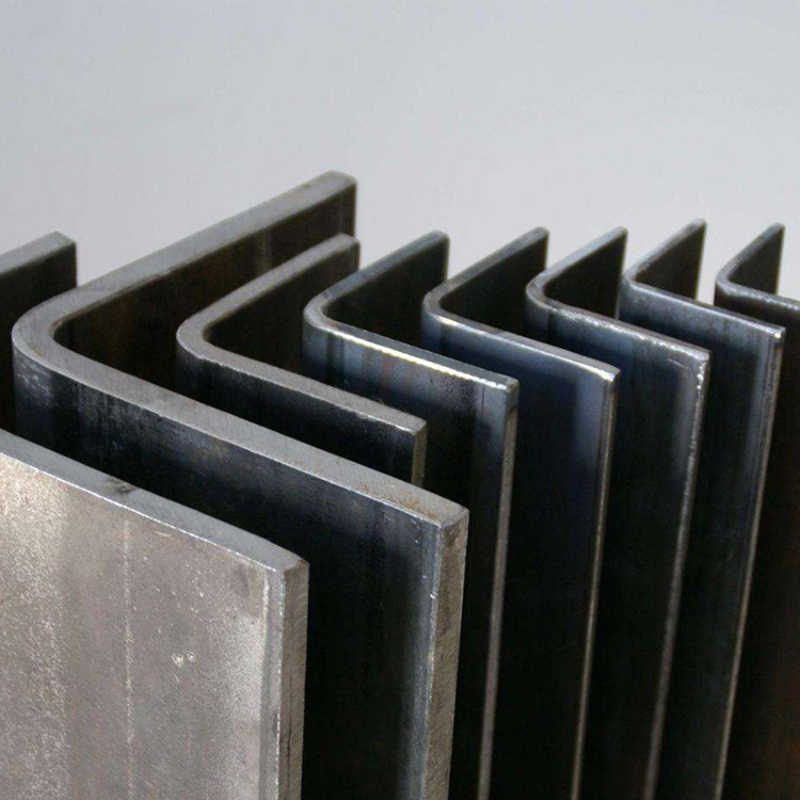

| Bayani: | Matsakaicin diamita 10 ~ 508mm |

| Wt: | 1.0-30mm, ko bisa ga abokin ciniki ta musamman request |

| Tsawon: | 2-20meters, ko bisa ga abokin ciniki ta musamman bukatar |

| Kunshin: | Daidaitaccen Kunshin Fitarwa |

| Nau'in bututu: | Boiler tube, daidai tube, inji tubing, Silinda tube, line bututu, da dai sauransu |

| Mill MTC: | Bayarwa kafin kaya |

| Dubawa: | Ana iya karɓar dubawar ɓangare na uku, SGS, BV, TUV |

| Dutsen tashar jiragen ruwa: | Duk wani tashar jiragen ruwa a kasar Sin |

| Lokacin ciniki: | FOB, CIF, CFR, EXW, da dai sauransu. |

| Tsawon farashi: | TT ko LC a gani |

| Ayyukanmu: | Za mu iya musamman bisa ga abokin ciniki ta requriement ko zane, marufi bisa ga abokan ciniki' request |